When: Course is scheduled at a specific time for students to attend. Face-to-face instruction at all class meetings. Location may be on campus or at a worksite.

Credentials typically take up to 10 business days to be processed after all grades are officially posted. NAIT will automatically issue your digital certification through our M圜reds system, and you will receive an email notification once your credential is ready. Students who successfully complete all required courses in the certificate of their choice will receive a digital credential.

#6 sigma training professional

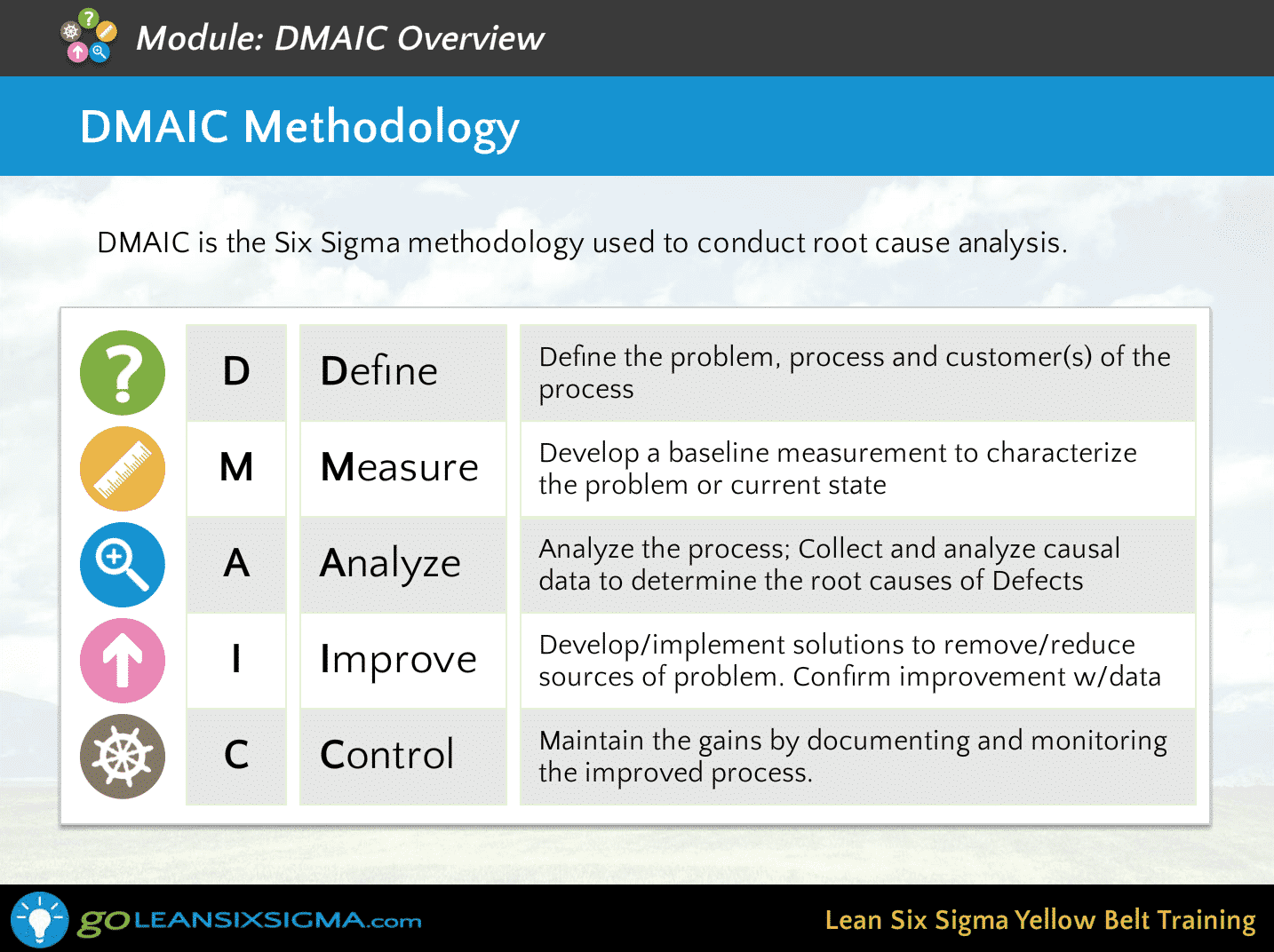

International Professional Development Certificates.Contact the International Training Team.Testimonials from International Partners.International and Intercultural Community Centre.Centre for Applied Disaster and Emergency Management.Academic Standing and Student Procedures.Applying for College and University Transfer Credits.Counsellors, Teachers and Community Organizations.Department of Culinary Arts and Professional Food Studies.School of Applied Sciences and Technology.Mawji Centre for New Venture and Student Entrepreneurship.are adept at applying DfSS with Minitab and the Excel add-in CQM_EfP.For more complex situations, coaching is recommended can themselves apply DfSS in their own work setting in situations that aren’t too complex.know the (statistical) techniques and have gained experience applying them.understand the position of DfSS within the existing (PCP milestone) procedure.know the DfSS phases, sub-steps and deliverables.see the importance of DfSS for their organization and their own daily work.But the following is true of all customized CQM training courses: a focus on the daily work environment practice-based issues are of primary importance coaching and on-the-job training is possible and there’s a 'lifelong' after-training service! The entire training course, including teaching materials, length and certification, is tailored to your needs and the training course’s target group. Application in the projects of the participants.To give you an idea, the following items are always addressed: The focus is on examples from, and application in, your organization. Fact-based decisions at every design step.ĬQM only delivers tailor-made training courses, so that we meet the specific needs of that customer.Technical Performance: How do I ensure the product will meet the specifications?.Voice of the Customer: How do I ensure that I now design what the customer really wants?.Human Dynamics: How do I know what the interests of the various stakeholders are and how do I get these aligned? For the Human Dynamics element, we work together with our longstanding partner, Berenschot.Project Definition: Why is the project important? What are we going to solve, and for whom?.In DfSS, particular attention is paid to the following aspects: Each phase is further divided into a number of sub-steps, each with their own deliverables and tools to help achieve those deliverables. The working method consists of a number of phases: pre-DfSS, Define, Identify, Design, Optimize, Verify and Monitor. While Lean SixSigma/DMAIC is all about improving existing processes by solving problems, DfSS is about preventing problems arising. It provides a structured, fact-based approach to the innovation process, from the Marketing briefing right through to product release. That’s the goal of Design for Six Sigma (DfSS). ‘First time right’: the product design that the customer actually wants and products that meet the specifications.

0 kommentar(er)

0 kommentar(er)